ABOUT US

Green One Environmental Technology (Shanghai) Co., Ltd.

While the pulp molding industry focuses on the primary disposable tableware market (e.g., plates, bowls, food containers), Greenoen Environmental Technology (Shanghai) Co., Ltd. specializes in the emerging field of pulp molding industrial food packaging. Its product matrix covers takeaway light meals, frozen ready-foods, nuts and preserved fruits, fresh meat, catering and other scenarios.

This strategy aligns with post-pandemic global catering structure changes and stricter environmental compliance requirements. Instead of simple containers, GREENONE offers a systematic packaging solution integrating protection, circulation, information and value empowerment:

- Superior Protection: Sophisticated structure and materials resist physical impacts, block microorganisms/oxygen, and ensure food freshness and safety throughout circulation.

- Efficient Circulation: Standardized and automated design fits large-scale production, intelligent warehousing and logistics, cutting customers' comprehensive operating costs.

- Information Interaction: As a core information carrier, it presents brand value, ingredients, traceability and shelf life, building positive brand associations and trust.

- Value Empowerment: Integrated functionality and aesthetics make packaging an extension of brand image and a competitive tool, boosting product added value and market share.

Pulp molding food packaging is widely used in home-delivered meals and in-flight catering. With innovative technology, GreenOne injects environmental protection, high efficien and cost-effectiveness into this field.

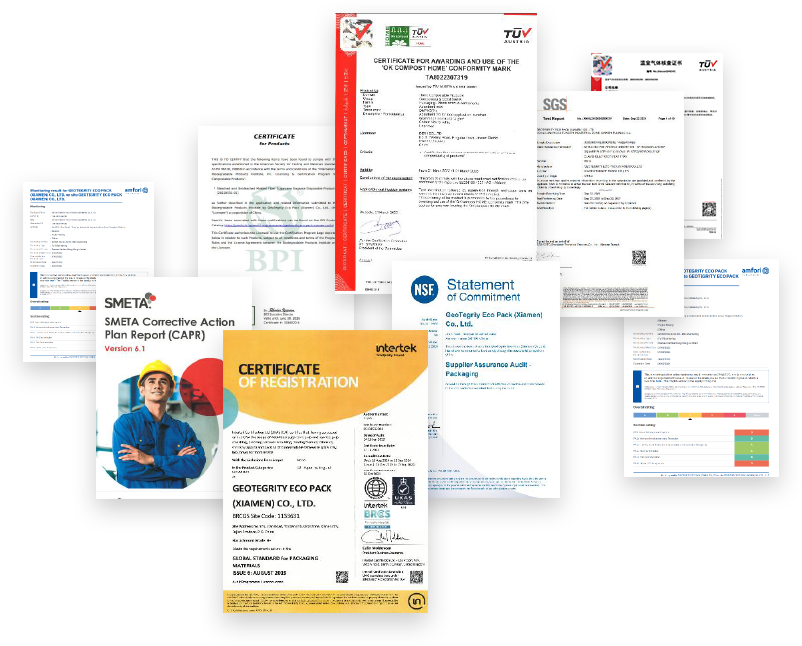

Authoritative Institution · Global Certification

Our cold chain food containers are made entirely of natural plant materials (sugarcane bagasse/bamboo fiber/straw) and have been certified by top international organizations:

Compostability Certification: OK COMPOST HOME, BPI, DIN

Food Safety Certification:BRCGS, FDA, NSF, TUV ISO 14064(Can directly come into contact with meat and cooked food)

Production Certification:Sedex, BSCI(Ensure human rights compliance in the supply chain)

2010-Now:Redefine the future of cold chain food packaging

Since the beginning of the global cold chain intelligent transformation, we have been the first to achieve:

Application of pure plants (sugarcane bagasse, bamboo, straw), sustainable, compostable, biodegradable, and renewable raw materials

Suitable for all scenarios from -40 ℃ to 240 ℃ (Freezing storage → Steaming box→microwave→oven cooking and heating)

90 day household composting degradation (compliant with Tuv ok compost home standards)

Integrity supply of compostable food containers (covering the entire product line from farm to table)

We have always been dedicated to research and development, possessing core technological advantages:

1.Physical Fiber Reinforcement Technology:

- Compressive strength compared with traditional bagasse products +100%.

- The blood water adsorption rate of meat trays is reduced by 90%.

- Exclusive salt-resistant and anti-corrosion technology for seafood trays, enhancing the performance of seafood packaging.

- RFID food safety traceability system.

2.Industry 4.0 Flexible Production Line:

- 72 hours to provide customized solutions.

- Support remote control and real-time quality monitoring.

3.Zero Waste Manufacturing System:

- 99.2% of production waste can be recycled and regenerated.

- 83% reduction in carbon footprint per ton of product (compared to petroleum based packaging).

Green One's Journey in Exploring Low-Carbon Containers!

We are not only creators of commerce but also steadfast advocates for plant-based environmental protection!

Green One is committed to transforming the current state of cold chain food packaging, driving the industry toward a lower-carbon, more eco-friendly, and sustainable future.

Planting the Future · Carbon Exploration for Sustainability

As the world's first solution provider specializing in plant-based cold chain packaging, Green One solemnly pledges:

Material Revolution:

Adhering to 100% wood-free recycled plant materials (sugarcane bagasse/bamboo/straw)

Circular Closed Loop:

Ensuring all products meet TUV OK COMPOST HOME industrial compostability standards

Responsible Innovation:

Implementing AI-driven low-carbon R&D systems to reduce trial-and-error carbon emissions by 80%

Standard Compliance:

√ ISO 14064 Carbon Footprint Verification

√ Sedex Ethical Supply Chain Certification

√ Annual ESG Reporting